Who We Are

A CENTURY OF IRON, GRIT, SWEAT, AND HONOR

A Century Of Iron, Grit, Sweat, and Customer Service

Lehigh Heavy Forge Corporation, a subsidiary of WHEMCO Incorporated, is the sole remaining super-heavy forging plant in North America. Our plant started forging in the 1880’s when the US Navy wanted to convert to iron clad ships, but did not have a source for forgings. Our facilities were the birthplace of the modern American defense industry. The Navy needed a source of forged armor plate and cannons in order to convert its fleet to iron clad ships. The forging plant continues to be a vital supplier of critical forged components for the defense of the United States. We have also grown to be a key supplier of commercial forgings to various industries by being innovative and responsive to customers’ needs.

Throughout the 1890’s the range of commercial products broadened. We dominated the market for large forgings for the power generation industry producing the field rings and rotor shafts for the large hydroelectric plants near Niagara Falls. The axle (45 ft long and weighing 56 tons) for the 1892-1893 Chicago World’s Fair Ferris Wheel was by far the largest forging produced to that time. The US maritime industry was served with forged crankshafts and propeller shafts.

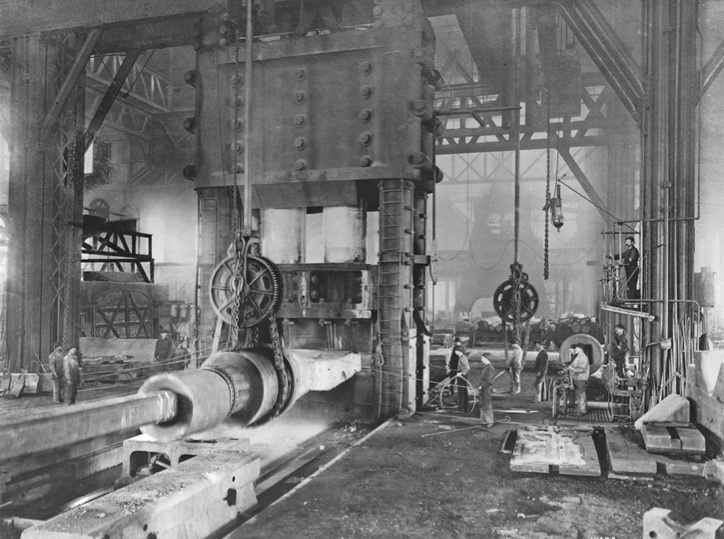

Forging Plant 1894

In the early 1900’s, the largest ingots produced to date (more than 162 tons) were used to produce components for a competitor’s forging press. Roosevelt’s Great White Fleet sailed around the world using our forgings. By 1918 over 35,000 workers were employed at the Bethlehem plant and the forging division. With the installation of an 8,000 ton press and numerous other equipment upgrades and additions, the forging plant maintained its status of the world’s finest.

As the demand for military forgings decreased after World War II, the production of commercial forgings grew. Bethlehem became a key supplier of turbine and generator shafts for the rapidly expanding electric power generation industry. Bethlehem was also a key supplier of critical forged components for the first commercial nuclear reactors built in the United States. In 1950’s, to preclude catastrophic hydrogen induced failures, vacuum degassing of the molten steel was pioneered in our facility.

Innovation and growth continued to be keystones of our business. A 10,000 ton oil hydraulic press with computer controls was installed in 1983. It is the largest Open Die Press in the Western Hemisphere. In the 1990’s, a new state of the art DC Arc melting furnace, ladle refiner, Vacuum Ladle Station were installed. The large ingots are double degassed – in the ladle vacuum station and during Vacuum Stream Degassing.

Forging Plant Today

In 1997 the forging division was purchased by WHEMCO Inc. to become Lehigh Heavy Forge. With significant capital investments, Lehigh Heavy Forge remains an innovative leader in the production of open die forgings. Using the 10,000 ton hydraulic open die press and 300 ton ingots, we can produce the largest open die forgings in the Western Hemisphere. Our 3,000 ton press is ideally suited for the production of smaller open die forgings. An experienced technical staff will develop innovative solutions to your unique forging needs. At Lehigh Heavy Forge, special order requirements are met using state of the art manufacturing facilities and production methods. Advanced computer modeling allows our engineers to accurately form complex shapes. With our skills as a world class Forgemaster, a full range of open die forgings can be produced for meet your requirements.

When you demand innovative solutions, allow Lehigh Heavy Forge to provide – Precision Forgings to Shape the Future….

We invite you to contact us, to learn more, and discuss your next project.